Water jet cutting is a technique, for slicing materials by employing a forceful stream of water blended with an abrasive element. This innovation has completely transformed the manufacturing sector enabling efficient cuts, across an array of materials.

Water jet cutting is a technique that harnesses the power of a high pressure water stream to slice through a range of materials, such, as metal, stone, glass and plastic. To enhance its effectiveness and accuracy the water is typically combined with a substance like garnet.

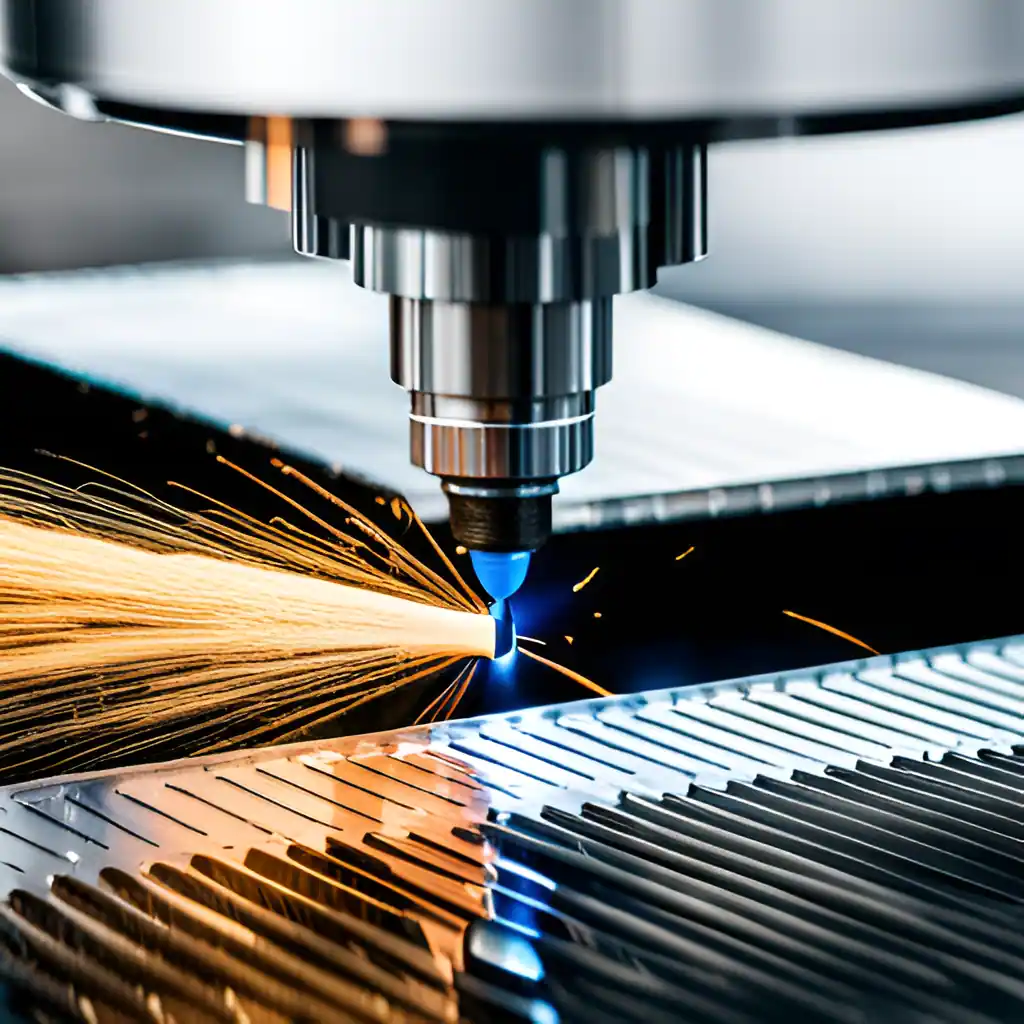

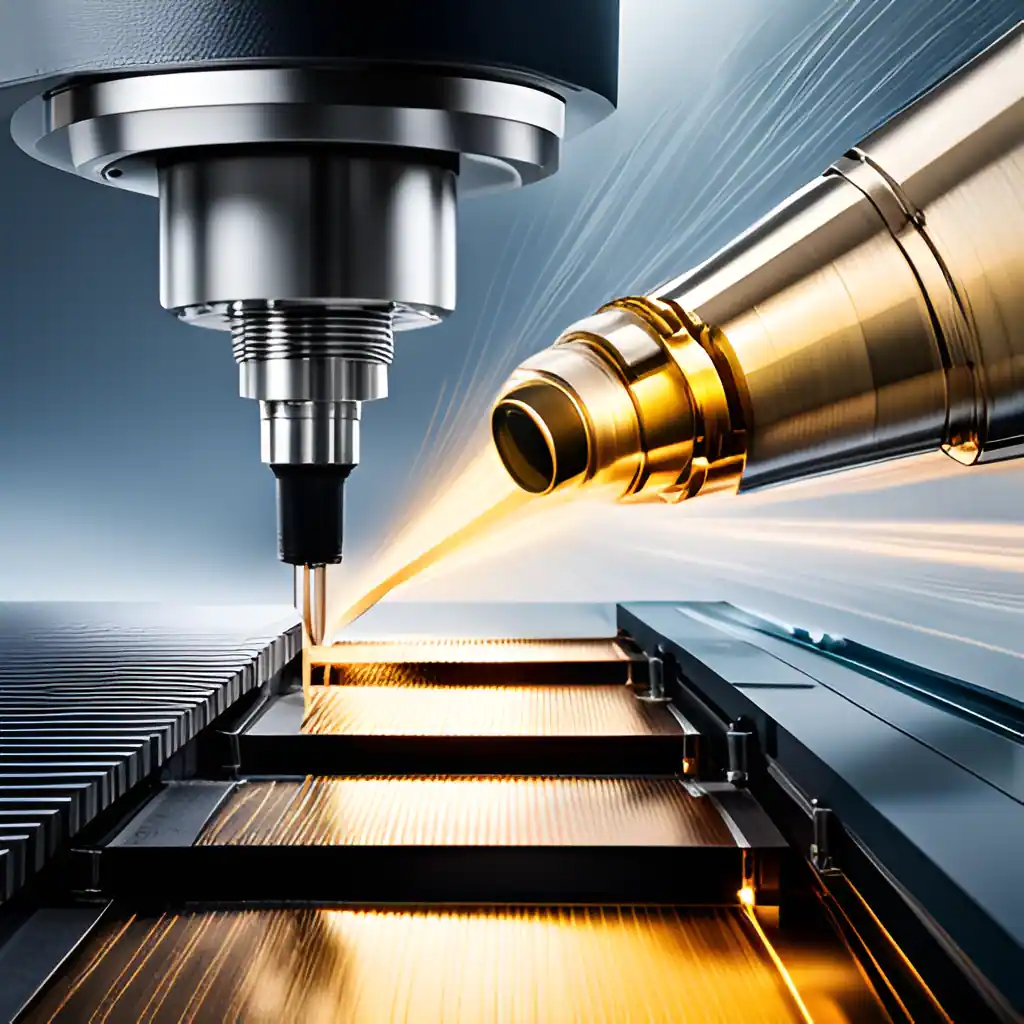

The process of water jet cutting commences with the development of a computer aided design (CAD) drawing. This drawing is then transformed into a format that can be understood by the cutting machine. Subsequently the machine diligently follows the path outlined in the CAD drawing using a high pressure pump to propel the water through a nozzle at speeds of up to 900 meters per second. Soon as it exits the nozzle the water forms a narrow stream capable of slicing through even the most resilient materials, with utmost precision.

Water jet cutting offers benefits compared to cutting methods. One of its advantages is the precision it achieves. With water jet cutting cuts can be made with accuracy down, to tolerances as small as 0.1mm. This level of precision makes it particularly well suited for industries like aerospace and medicine where accuracy’s of importance.

Another advantage of water jet cutting lies in its versatility. It is capable of cutting a variety of materials ranging from metals and plastics to stone and glass. This versatility makes it a preferred choice for manufacturers who regularly work with types of materials. Furthermore water jet cutting does not generate heat affected zones (HAZ) eliminating any concerns, about warping or distorting the material being cut.

Water jet cutting is a technology that finds its applications, across various industries. For instance in the aerospace sector it is employed to precisely cut shapes and designs from metals and composites. In the industry water jet cutting plays a role in fabricating parts for engines, transmissions and body panels.

One noteworthy advantage of water jet cutting lies in its capability to cut through a range of materials with ease – be it rubber or tough metals. This makes it an ideal choice, for industries that often deal with materials requiring cuts. Additionally water jet cutting offers precision enabling tolerances and intricate designs to be achieved effectively.

Water jet cutting has become a component of Dubais construction and manufacturing sectors. Its versatility, in cutting materials, such as metals, plastics and composites has brought about opportunities for creativity and advancement.

Interestingly recent data indicates that the need for water jet cutting services, in Dubai has consistently risen in the years. This can be attributed to the cities flourishing construction industry, which necessitates efficient cutting methods to cater to architectural designs.

Thank you for your time

Thank you for taking the time to learn more about our water jet cutting services. If you have any questions or would like to discuss a project, please don’t hesitate to contact us.

You can reach us by phone at +971-556-673074, email us at order@galaxystonecare.tech, We look forward to hearing from you!